How this 3rd party endoscope repair service rivals the OEM

Two years ago, Rochester Endoscopy and Surgical Center in Rochester Hills, Mich., entered into a five-year service contract with an OEM endoscope company, for 30 endoscopes. The surgery center entered the contract as it prepared to move into a new facility. Due to size limitations the center only used 25 endoscopes in the procedure rotation.

After moving to the new, larger surgery center, Brian Micheals, head of materials management, was ready to incorporate the five other scopes into the procedure rotation. He was considering adding them onto his OEM service contract, when he learned about a third-party endoscope repair company Total Scope.

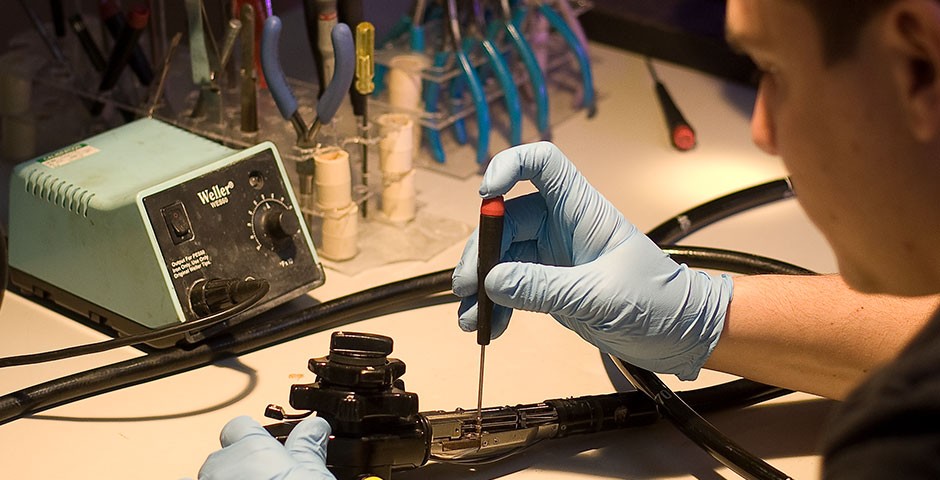

Founded in 1992, Total Scope is an independent endoscope and surgical camera repair business, focused on fixing scopes quickly and up to original equipment manufacturer quality standards. Total Scope is one of the only ISO-13485-certified endoscope repair companies. ISO-13485 certification is a voluntarily program that ensures medical devices and related products are quality controlled.

Mr. Micheals and Rochester Endoscopy met with a Total Scope representative and after hearing about the company and its quality standards, the decision to move forward with Total Scope was an easy one.

That was in 2017; now Mr. Micheals and Rochester Endoscopy plan to move the other 25 scopes onto their contract with Total Scope in accordance with the terms of the original OEM contract. Citing the company's exceptional turnaround time, customer service and price, both Mr. Micheals and Rochester Endoscopy's physicians were impressed with the quality of Total Scope's repairs.

Total Scope stands out in the crowded endoscope repair field due in part to their ISO-13485 certification, the expertise of their staff and the quality of their repairs. Total Scope and third-party scope repair, in general, may be an option for endoscopy centers and ASCs. Efficient and effective repairs don't need to take weeks and they don't have to devastate a center's bottom line. That's why Boston Scientific partnered with Total Scope to offer their customers a quality scope repair option to get endoscopes back into the hands of GIs faster.

Exploring the third-party endoscope repair market

Third-party endoscope repair companies are unregulated, said Total Scope President Denis Kennedy. "Anybody can do scope repair," he said. "If you know how to crack open a scope, you can source parts. You can start tomorrow in a basement or garage, so to speak."

The International Organization for Standardization introduced ISO-13485can help customers distinguish a good shop from a questionable one. The voluntary certification denotes a certified body has established a quality management system and adheres to the system's established standards in its quality management practices.

ISO certification matters because it demonstrates a company went the extra mile to outfit their facility for quality. To become ISO-certified, a company needs to satisfy several requirements that encompass the entirety of their business including: handling and delivery, internal quality audits and employee training.

Recognizing the benefits of certification, Total Scope's Philadelphia facility achieved ISO-13485 certification in 2000, and its newly opened Nashville, Tenn.-based facility achieved the certification in March 2017. Both certifications are specifically for medical instrumentation, including flexible endoscopes. Mr. Kennedy saw the certification as a way to standout in the field and earn customer confidence.

To earn the certification, Total Scope had to write out a comprehensive set of work instructions describing the entire repair process in depth. The company also had to create training and operating logs, establish a recall system, create a lot numbering system, and develop a closed loop complaint system, among other efforts.

"[Customers believed the industry] wasn't fixing things the right way, that shops weren't getting parts from the OEM," Mr. Kennedy said. "ISO certification gives the customer a sense of security. We have to follow certain guidelines. We have to follow OEM specifications and there have to be certain protocols in place and training methodologies that 'local guys' don't have to follow."

The FDA, too, sees the benefits of the ISO program. In the Spring of 2018, the FDA announced that it intended to adopt the ISO-13485 for Quality System regulation, and would be proposing rules to that end.

In the announcement, the Association for the Advancement of Medical Instrumentation's Wil Vargas said, "This bold step by the FDA seems logical, considering the role of ISO-13485 as the foundation for the Medical Devices Single Audit Program, currently operated by Australia, Brazil, Canada, Japan and the U.S."

Another aspect that sets Total Scope apart from the field is the company's rigorous process for ensuring parts are up to OEM standards. Scope manufacturers often keep part specifications proprietary and do not offer training in scope repair. To address this and keep its staff's repair knowledge current, Total Scope has developed and implemented systems to ensure that their technicians are current with new product specifications, validation of repair processes, and so forth.

When administrators go to an ISO-13485 certified shop, the scope they get back is certified by Total Scope, Mr. Micheals said.

The Total Scope experience

Total Scope's commitment to ISO certification and its rigorous parts manufacturing process led Boston Scientific to form a partnership with the company in June 2017. Boston Scientific and Total Scope entered into an agreement to promote the company's repair services.

Boston Scientific's National Manager of Scopes and Services Ryan Rector said the company looked at more than 20 repair shops before deciding on Total Scope.

"I think if you look back at the history of Boston Scientific and see how important quality is [to us], to be able to make sure someone follows the same quality processes we do is very important," Mr. Rector said. "Ultimately [quality repairs] relates back to patient success and reducing complications. Whether it's devices or scope repair, all that's based on quality processes."

Boston Scientific formed the partnership with Total Scope to accommodate its customers' scope repair needs. Compared to OEM repairs, which may take weeks, Total Scope touts turnaround times as low as three days. For some minor repairs, the company can even do one-day turnarounds. Other endoscope repair shops in the field average around seven to 10 days, Mr. Kennedy said. Total Scope can achieve quick turnaround times because of the infrastructure it has in place.

Total Scope also leverages that infrastructure to promote damage prevention. The company offers preventative maintenance inspections and offers educational resources to its clients to teach centers how to properly care for and handle products.

"[These services] help clients lower repair instances," Mr. Kennedy said. "What we're trying to do is catch a small repair before it becomes a major repair. If we catch these repairs at a minor level, we'll be able to get the scopes back faster and create less downtime for them."

Talking with both Boston Scientific and Total Scope, Mr. Rector attests that the turnaround times Total Scopes promises are a reality.

"OEMs can average a week and a half on minors and three to four weeks on majors," he said. "With Total Scope, if there's a break on Monday, it's back Wednesday. Right now, they're averaging under three days on majors. Centers are able to get their scope back the same week, which is so important to be able to run your center."

"It's a true partnership," Mr. Kennedy said. "We want you to have the most opportunistic uptime. We want zero defects at the table. If we see your scopes, we're just driving down the profit of our contracts."

Having another option is important for endoscopy centers. When Mr. Micheals was deciding between adding the scopes to Rochester Endoscopy's OEM contract or going to Total Scope, he gave consideration to both turnaround time and pricing.

Mr. Micheals said when it came to repairs, Total Scope was averaging two to three days. Rochester uses a blackboard scheduling system, so everyone at the center knows the procedure caseload. Rochester performs a majority of its procedures on Friday and often send any scopes in need of repair out on Monday and get them reprocessed and back in the surgeon's hands before the first patient enters the door Friday morning. When it came to cost in this case, Total Scope's pricing was half of what the cost would have been if they added the scopes to the OEM contract. Although Rochester is contracted with Total Scope, the company bills monthly and assured Mr. Micheals if there was ever an issue, the Total Scope contract could be voided.

The partnership between the two companies also offers cost savings that are passed onto the customer. Mr. Rector said " “Accounts are getting better pricing because now there is a legitimate offering. We're just putting another player in the field to make it competitive and to ensure the customer is getting better pricing."

Mr. Kennedy elaborated on the pricing. When Total Scopes enters into a contract with a client, it's for a set annual rate. No matter how many repairs a customer has they will never have to pay more. Unlike some competitors that charge by repair, Total Scope wants to keep endoscopes in a physician's hands and out of their shops.

"Ever since [we signed on], they've been an excellent company to send scopes to," Mr. Micheals said. "They're incredibly attentive. I frequently get emails and calls from managers, making sure everything is going well and making sure we're happy with the scopes we're getting back."

The three buckets of scope repair

When it comes to considering a third-party endoscope repair center, Mr. Rector offered insights into what he tells Boston Scientific's clients when they're considering a partnership. He broke down the entire process into three buckets.

Efficiency is the first bucket. Broken scopes impede business. Without scopes, GIs can't perform procedures and their centers can't make patients healthier. If a repair takes several weeks, centers will suffer from decreased revenues.

Quality is the second bucket. While there are repair shops that undercut Total Scope and OEM on pricing, repair quality at these shops can be lacking. "It's great if you're cheaper, but if the quality is so poor and the scope keeps breaking down, it's ultimately going to cost you more money," said Mr. Rector.

Risk management is the third bucket. Mr. Rector cited the partnership between Boston Scientific and Total Scope when talking about risk management. Service contracts make up about 20 percent of a center's capital purchases. If a center isn't happy with a contract, they are stuck in the contract until it expires.

The bottom line

Total Scope was started based on the premise that everything ties back to quality. From the ISO-certification, to ensuring customers are beyond satisfied with repairs, Total Scope is an alternative to OEM repairs and OEM's restrictive contracting that doesn't sacrifice quality. Boston Scientific recognized the many benefits Total Scope offered and partnered the shop to ensure its customers wouldn't have to sacrifice revenue in the event of a scope break. Centers have options when it comes to repairs, and at the end of the day, administrators need to go with what drives the most value. For evidence of that, look no further than Mr. Micheals and Rochester Endoscopy Center.

"Total Scope came up from the bottom, and if they stay on the path they are on I think they'll be a very successful company," he said. "From the level of repairs to how they go about their customer service, I think Total Scope will make a big impact in the scope world if they continue [doing business] the way they're doing it."